Coil Springs are more common as they are the most used in mechanics.

As a rule, they are made of steel wire wound in a cylindrical or conical gel form. The shape of the steel wire can be rectangular, circular, square, etc.

Coil springs can work by compression, traction or torsion.

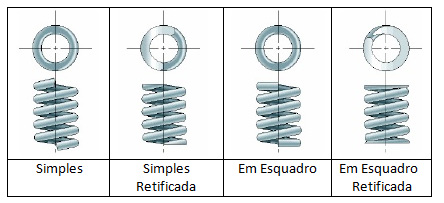

Compression helical springs are meant to accumulate forces during their compression and apply them in a “pushing” motion. They are built in a parallel helical or conical shape.

They are generally produced with cylindrical wires, and in specific cases, when it is necessary to apply greater forces in reduced spaces, using square, rectangular or otherwise- shaped wires.

LO = Uncompressed height

Da = External Ø

Di = Internal Ø

d = Ø of the Wire

P = Pitch

Nv = Number of Active Coils

Nt = Total number of Coils (Nv+2)

They are formed by spirals that, when they are compressed by some force, reduce the space between themselves, thus diminishing the length of the spring. The active coils (Nv) are the coils that get deformed when the spring is loaded, whereas the inactive coils at each extremity do not get deformed. The extremities of the compression springs are prepared according to the application needs, to allow a greater stability and fit on the base that will support it.

The torsion helical springs are created to receive torsion requests on their extremities. In other words, they have rods that can be straight or curved where the force is applied.

They’re generally designed to work around an axis, and when they are subjected to lateral forces, applied on the rods, they tend to roll their coils further.

They are normally produced with cylindrical, square or rectangular wires, or of any other special shape.

De = External diameter of the spring

Di = Internal diameter of the spring

H = Length of the spring

d = Diameter of the wire section

p = Pitch

nº = Number of coils

r: = Length of the lever arm

a: = Angle between the extremities of the spring

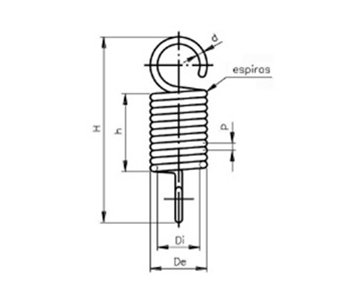

Traction helical springs are similar to compression helical springs. However, they need special extremities for the load to be applied.

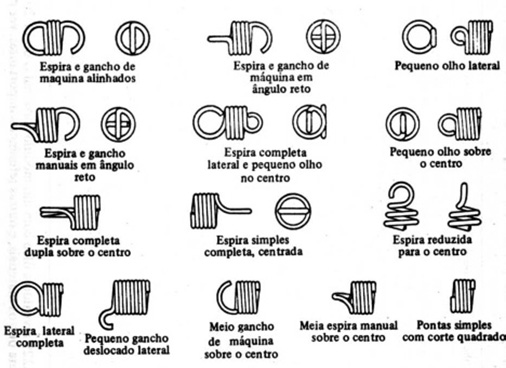

These extremities are called hooks and can have several shapes.

When they are subjected to the action of a “pushing” force, the space between the coils increases, thus increasing its length.

H = Uncompressed height

h = Compressed height

De = External Ø

Di = Internal Ø

d = Ø of the Wire

P = Pitch

N = Number of Coils

Traction spring hook shape